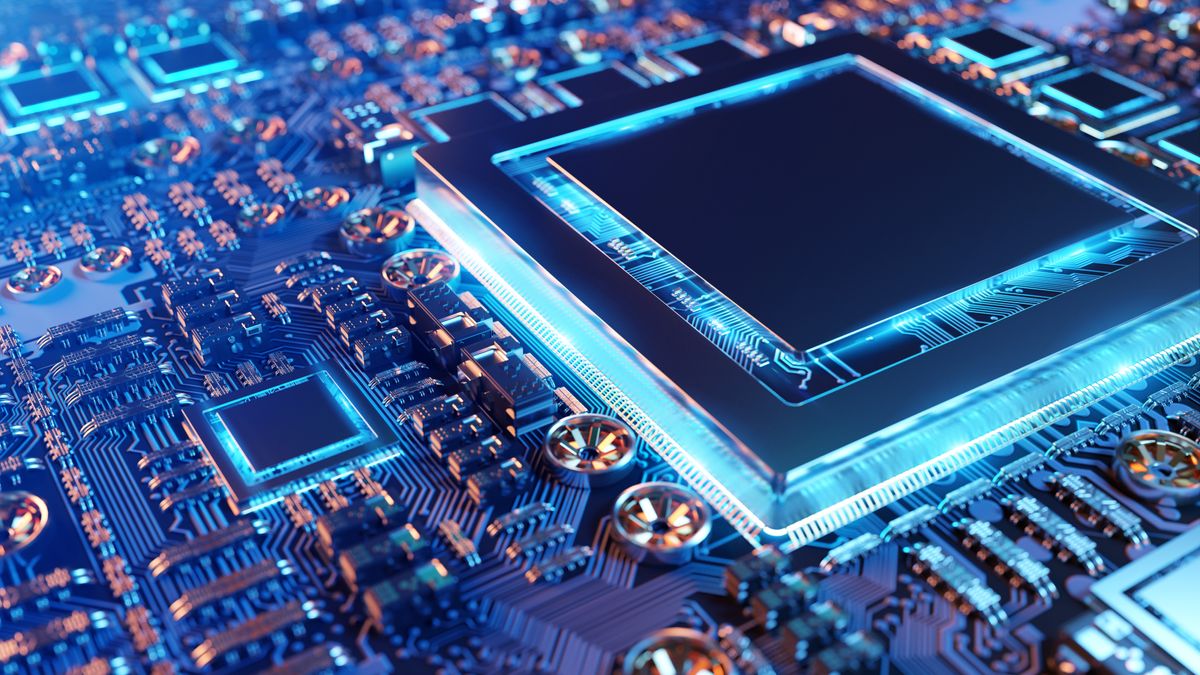

India's Ambitious Semiconductor Fabrication Facility Plan Set to Revolutionize Chip Production

The Indian government is set to play a pivotal role in the development of a semiconductor fabrication facility, reportedly contributing a remarkable 90% of the total cost. This announcement comes at a time when demand for semiconductor manufacturing is surging, fueled by the explosive growth of artificial intelligence (AI) and related technologies.

The construction of fabrication plants, commonly referred to as fabs, is notoriously lengthy. In fact, the process often lags behind market demand by several years, which can create significant challenges for businesses aiming to capitalize on emerging tech trends.

L&T Semiconductor Technologies (LTSCT), a fabless chip startup supported by the prestigious Indian engineering firm Larsen & Toubro, has set its sights on building a $10 billion wafer fabrication facility in India. This ambitious project is not merely a speculative endeavor; it is closely tied to LTSCT's goal of achieving $1 billion in annual revenue by the 2026–2027 fiscal year, as reported by eeNews Analog.

Founded in 2023 as a wholly owned subsidiary of Larsen & Toubro, LTSCT was established with the mission to design a diverse range of semiconductor components. These include MEMS sensors, analog and mixed-signal integrated circuits (ICs), radio frequency (RF) chips, and smart power devices. Although the company has yet to commence shipping chips, its CEO, Sandeep Kumar, is optimistic that commercial production will kick off in the latter half of 2025.

In an interview with Business Standard, Kumar emphasized the financial scale of the fab plant, stating, “A fab plant will require an investment of over US$10 billion. Even with subsidies, it will mean an investment of US$1 billion.” He explained that the initiation of the company's fab plans is contingent upon achieving that $1 billion revenue milestone by the 2026–2027 fiscal year.

LTSCT is strategically positioned to benefit from India’s broader semiconductor initiative, which includes a substantial $10 billion incentive program that was launched in 2021. This government backing is crucial for the success of India's semiconductor landscape and aligns with global trends where governments are increasingly investing in local chip production capabilities.

It is noteworthy that the anticipated contribution from the Indian government is significantly higher than the support typically offered in similar initiatives worldwide. Kumar has acknowledged that LTSCT does not plan to seek external funding beyond this substantial government investment.

Looking ahead, eeNews Analog highlighted that LTSCT’s long-term vision includes transitioning from a fabless design entity to an integrated device manufacturer (IDM), a strategic shift that could enhance the company’s market position and operational capabilities.

In its early development stage, LTSCT has already garnered over $300 million in funding from its parent company, Larsen & Toubro. This financial support is aimed at bolstering its design initiatives, with plans to roll out 15 chip products by the year 2027, marking a significant leap forward in India's semiconductor manufacturing ambitions.