Revolutionizing Grocery Shopping: Ocado's Automated Warehouse System

In an age where technology continues to redefine our daily lives, a groundbreaking development in grocery shopping is emerging from the United Kingdom. Ocado, a pioneer in the field of online grocery delivery, has introduced a fully automated warehouse system known as the Hive. This innovative system is transforming the grocery shopping experience, enabling customers to have their complete orders picked, packed, and prepared for delivery in an astonishingly short time of just five minuteswithout any human touch at all.

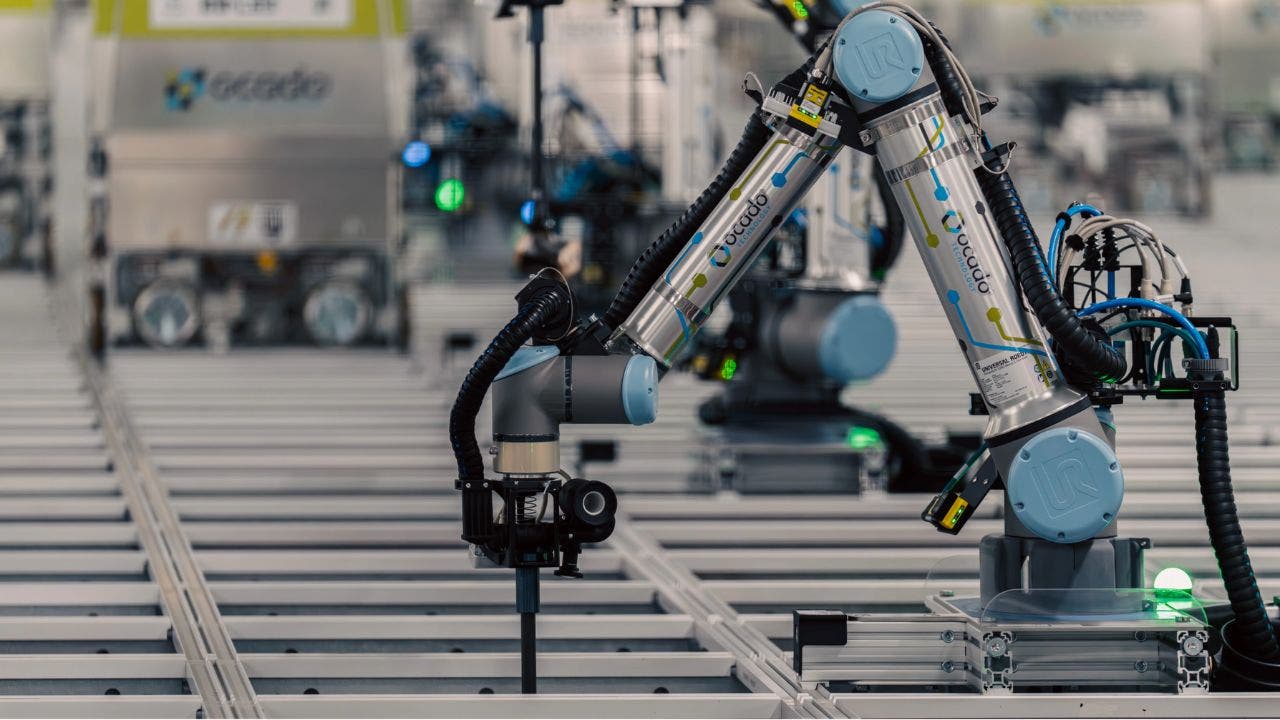

The core of this revolutionary system lies within Ocados Customer Fulfilment Centres (CFCs), where the Hive operates as a massive, intricate 3D grid filled with thousands of grocery products. Imagine a bustling metropolis of robots, referred to as bots, racing through the aisles at speeds nearing 9 miles per hour. These bots are expertly managed by an AI-driven air traffic control system that communicates with each robot a staggering ten times every second. This rapid and precise coordination allows the bots to work in unison to pick and transport items to be packed by robotic arms, all with remarkable accuracy and efficiency.

At the heart of the Hives operation is Ocados advanced smart platform, a sophisticated integration of artificial intelligence, robotics, and automation. This platform is specifically designed to address the unique challenges that come with online grocery shopping. Factors such as narrow profit margins, a wide variety of items that customers may order, and the necessity to handle products at different temperatures all contribute to the complexity of this task. However, Ocado has dedicated over two decades to developing this innovative technology, which has resulted in a system capable of picking and packing a 50-item grocery order in mere five minutesan astonishing six times faster than conventional methods.

These robotic arms are equipped with cutting-edge computer vision and deep learning capabilities, allowing them to make intelligent decisions in real-time. Rather than simply following a pre-set packing order, the robots can adapt to changes and pack groceries in a way that optimizes space and safety, even as they work without prior knowledge of what items are coming next. Furthermore, Ocado employs digital twin technology to create a virtual replica of the warehouse. This allows them to simulate and refine processesfrom anticipating customer demand to optimizing delivery routesthereby facilitating rapid innovation and minimizing risks before implementing changes in actual operations.

The implications of the Hives speed and scale are nothing short of revolutionary. Orders that traditionally took over an hour to assemble manually can now be completed in a fraction of the time, with the system capable of processing multiple orders simultaneously. Additionally, Ocados warehouses boast an inventory capacity that is up to 78% larger than that of conventional supermarkets, providing customers with an extensive selection of products that can be tailored to individual preferences.

One of the most significant benefits of this automated system is its potential to drastically reduce food waste. Ocado reports a waste rate that is a mere fraction of the industry average, thanks to their innovative forecasting methods and precise inventory management strategies. Another advantage of the Hives design is its modularity, allowing retailers to scale operations according to their needs. Whether its a large warehouse serving an entire region or a smaller fulfillment center located closer to customers for faster service, the technology is adaptable.

For those residing in areas served by Krogers delivery network in the United States, groceries can be conveniently ordered through the Kroger website or mobile application. Behind the scenes, these orders are swiftly picked and packed by hundreds of AI-driven robots operating out of a fulfillment center known as the Hive. Subsequently, a Kroger associate delivers the groceries directly to customers doors, often in a timeframe that surpasses traditional delivery methods. This collaboration between Ocado and Kroger signifies a significant advancement in grocery delivery, marrying cutting-edge technology with everyday consumer needs.

Interestingly, Ocados technological innovations extend beyond the realm of grocery shopping. The same robotics, AI, and automation techniques are being explored for diverse applications, including vertical farming, assisted living facilities, car parking solutions, and even airport baggage handling systems. The Hive is not just a game-changer for grocery logistics; it is paving the way for smarter, more efficient automation across numerous industries.

As we contemplate the future of grocery shopping, it is fascinating to envision a world where our entire grocery order can be picked and packed in just five minutes, all without a human hand ever touching our food. Ocados Hive harnesses the power of smart robots and AI to make grocery shopping not only faster but also easier and more reliable than ever before.

As we stand on the brink of this technological revolution, we invite you to share your thoughts. Would you be comfortable with a robot handling your groceries, or do you prefer the traditional method of human involvement? Let us know by reaching out to us at Cyberguy.com/Contact.